Get instant quotes on custom CNC Machining Copper parts for prototypes, small batch and mass production with lowest cost.

Fast delivery time with 5 working days.

50+ metal, plastic and woods, 30+ surfaces finishes

ISO9001:2015, SGS Certificated and RoHS report

ABS (Acrylonitrile Butadiene Styrene), a versatile and widely used polymer, finds new dimensions of

precision and functionality when combined with CNC (Computer Numerical Control) machining. This

exploration delves into the world of CNC machining ABS, unveiling its attributes, applications, and

crucial insights.

Unlocking the Potential of CNC Machining ABS

The fusion of ABS and CNC machining unlocks a world of precision and adaptability, where polymers meet

innovation:

1. Polymer Performance: ABS’s blend of strength, toughness, and impact resistance

pairs seamlessly with CNC machining, yielding components that are both durable and functional.

2. Precision Redefined: The inherent stability of ABS forms the foundation for

meticulous accuracy, allowing CNC machining to create intricate details with unparalleled finesse.

3. Material Versatility: ABS’s adaptability, coupled with CNC machining precision,

results in parts that can take on various forms, making it ideal for diverse applications.

4. Aesthetic Flexibility: CNC machining preserves ABS’s versatility, enabling the

creation of components with different finishes, textures, and colors.

Applications Elevated by CNC Machined ABS

CNC machining ABS amplifies precision and adaptability in applications where strength, impact

resistance, and aesthetic appeal converge:

1. Consumer Electronics: CNC-machined ABS parts find their place in consumer

electronics, where durability and functionality are combined with appealing design.

2. Prototyping Perfection: The precision of CNC machining ABS makes it an excellent

choice for rapid prototyping, allowing designers to create functional models.

3. Automotive Innovation: ABS, enhanced through CNC machining, contributes to

lightweight and impact-resistant automotive components.

4. Household Goods: From appliances to decorative items, CNC-machined ABS components

offer both aesthetics and functionality for everyday use.

5. Industrial Applications: CNC-machined ABS parts serve various industrial sectors,

where durability, ease of processing, and versatility are essential.

Navigating the Landscape of CNC Machining ABS

1. Tool Mastery: Selecting cutting tools optimized for ABS’s properties ensures

efficient machining and excellent surface finishes.

2. Cooling Strategies: Thoughtful coolant application aids in heat management during

machining, optimizing chip removal while preserving material integrity.

3. Precision Chip Control: Adapting chip control techniques addresses ABS’s chip

formation tendencies, promoting a smooth and efficient machining process.

4. Design for Functionality: Collaborating with experienced machinists during the

design phase ensures that designs align with both CNC machining capabilities and ABS’s

characteristics.

In the Spotlight: FAQs and Customer Testimonials

FAQs on CNC Machining ABS:

- Can CNC machining achieve intricate designs on ABS parts? Absolutely. CNC

machining excels at delivering intricate precision on ABS components, allowing for the creation of

complex geometries. - How does CNC machining ABS contribute to functionality? Precision machining

maximizes ABS’s mechanical properties, resulting in components that combine strength, toughness, and

versatility.

Customer Testimonial – Michael:

“DP Machining has been my trusted partner for CNC machining ABS projects. Their commitment to

precision and innovation has consistently amazed me. DP Machining’s dedication to delivering

high-quality results, coupled with their technical expertise, makes them the perfect choice for CNC

machining ABS components.”

CNC machining ABS encapsulates precision and functionality, where polymers meet adaptability. From

electronics to prototyping, this partnership navigates diverse applications with grace and

cutting-edge craftsmanship. When excellence beckons, DP Machining emerges as the guiding star,

offering expertise, technology, and unwavering commitment to crafting perfection in the realm of CNC

machining ABS.

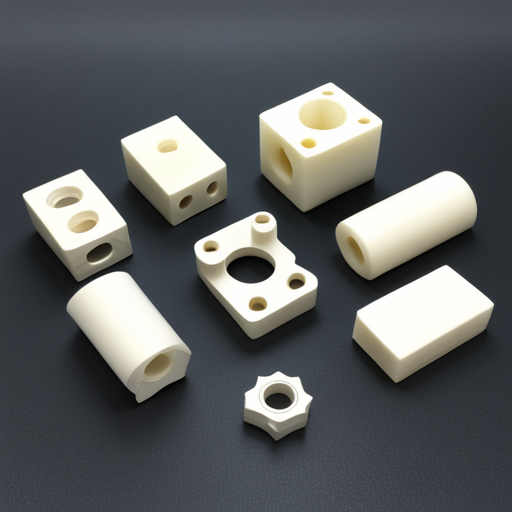

CNC Machining ABS Sample

Would you like us to do the work for you? Please contact us and tell us the requirement, we will reply you in 2 working days.