PEEK (Polyether Ether Ketone), a robust and high-performance polymer, embarks on a transformative journey when

united with CNC (Computer Numerical Control) machining. In this exploration, we delve into the world of CNC

machining PEEK, unveiling its attributes, applications, and crucial insights.

Elevating Precision with CNC Machining PEEK

The amalgamation of PEEK and CNC machining ushers in a realm of precision and endurance, where advanced polymers

meet innovation:

1. Advanced Performance: PEEK’s exceptional mechanical properties blend seamlessly with CNC

machining, yielding components that exhibit strength, toughness, and chemical resistance.

2. Precision Refined: PEEK’s inherent stability forms the basis for meticulous accuracy,

allowing CNC machining to craft intricate details with unparalleled finesse.

3. High-Temperature Champion: PEEK’s excellent thermal stability, coupled with CNC machining

precision, results in parts that perform under extreme temperature conditions.

4. Versatile Engineering: PEEK’s adaptability, enhanced through CNC machining, makes it suitable

for a wide range of applications that demand durability and reliability.

Applications Transformed by CNC Machined PEEK

CNC machining PEEK brings precision and endurance to applications requiring high-performance polymers:

1. Medical Advancements: CNC-machined PEEK components play a pivotal role in medical devices,

where biocompatibility, strength, and precision are paramount.

2. Aerospace Innovation: PEEK, crafted with precision through CNC machining, contributes to

lightweight and durable aerospace components.

3. Oil and Gas Exploration: CNC-machined PEEK parts excel in the demanding environment of oil

and gas exploration, showcasing resistance to chemicals and extreme conditions.

4. High-Tech Electronics: PEEK’s insulation properties, combined with CNC machining, are ideal

for electronic components that require durability and thermal stability.

5. Industrial Excellence: CNC-machined PEEK parts find their place in industrial machinery,

where their mechanical resilience and chemical resistance provide essential solutions.

Navigating the Realm of CNC Machining PEEK

1. Tool Expertise: Selecting cutting tools optimized for PEEK’s properties ensures efficient

machining and excellent surface finishes.

2. Cooling Strategies: Thoughtful coolant application aids in heat management during machining,

optimizing chip removal while preserving material integrity.

3. Precision Chip Control: Adapting chip control techniques addresses PEEK’s chip formation

tendencies, promoting a smooth and efficient machining process.

4. Design for Endurance: Collaborating with experienced machinists during the design phase

ensures designs harmonize with both CNC machining capabilities and PEEK’s attributes.

In the Spotlight: FAQs and Customer Testimonials

FAQs on CNC Machining PEEK:

- Can CNC machining achieve precision on PEEK parts? Absolutely. CNC machining excels at

delivering precision on PEEK components, ensuring consistent accuracy. - How does CNC machining PEEK contribute to high-temperature applications? Precision

machining enhances PEEK’s high-temperature performance, making it suitable for environments with extreme heat.

Customer Testimonial – Sarah:

“DP Machining has been my trusted partner for CNC machining PEEK projects. Their commitment to precision and

innovation never ceases to amaze me. DP Machining’s dedication to delivering high-quality results, along with

their technical expertise, makes them the perfect choice for CNC machining PEEK components.”

CNC machining PEEK epitomizes precision and endurance, where high-performance polymers meet innovation. From

medical advancements to aerospace feats, this partnership navigates diverse applications with grace and

cutting-edge craftsmanship. When excellence beckons, DP Machining emerges as the guiding light, offering

expertise, technology, and unwavering commitment to crafting perfection in the realm of CNC machining PEEK.

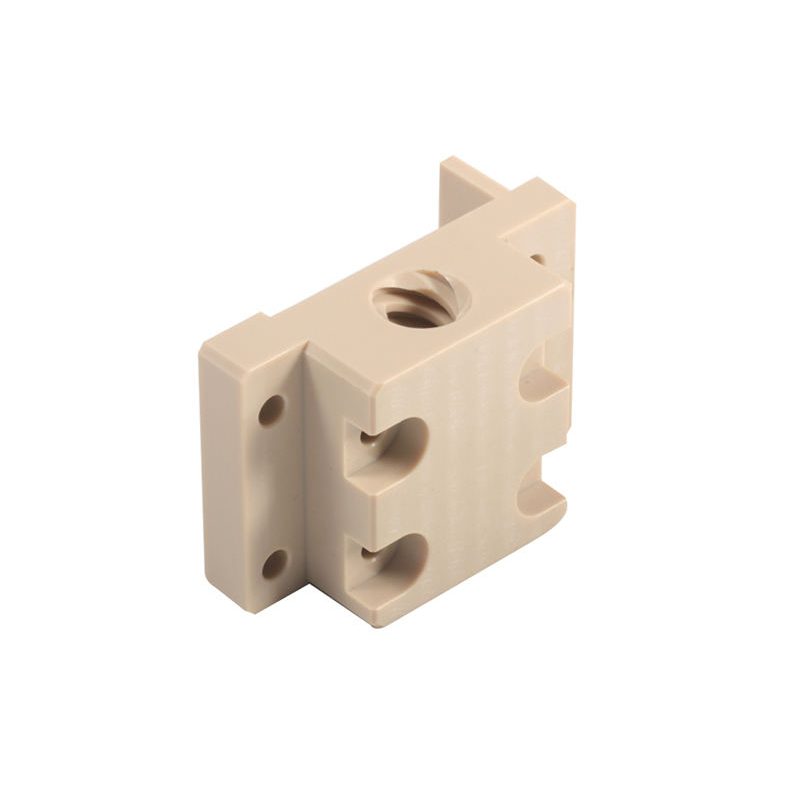

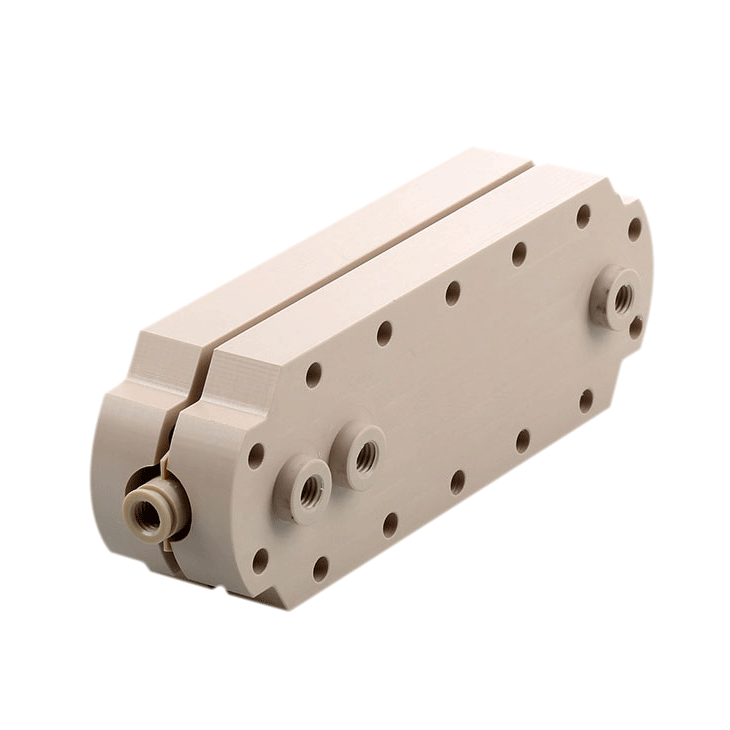

CNC Machining PEEK Sample